Sponsored Content, Presented by Montrose Environmental

Sustainable and Consistent

Full-scale regenerable ion exchange resin (RIEX) systems designed for remediation and containment of PFAS have been operating successfully for over six years. In Australia, one such system, which began operations in May 2019, offers insights into the efficiency, sustainability, and practicality of RIEX systems for PFAS removal.

Work on this project began in late 2018 with extensive feasibility studies and technical evaluations to assess various treatment techniques. The techniques included granular activated carbon, single-use ion exchange resin, and RIEX. The groundwater PFAS concentrations necessitated treatment objectives aligned with Australian Health Based Guidance values—with a particular focus on addressing PFOS and PFHxS (combined), and PFOA.

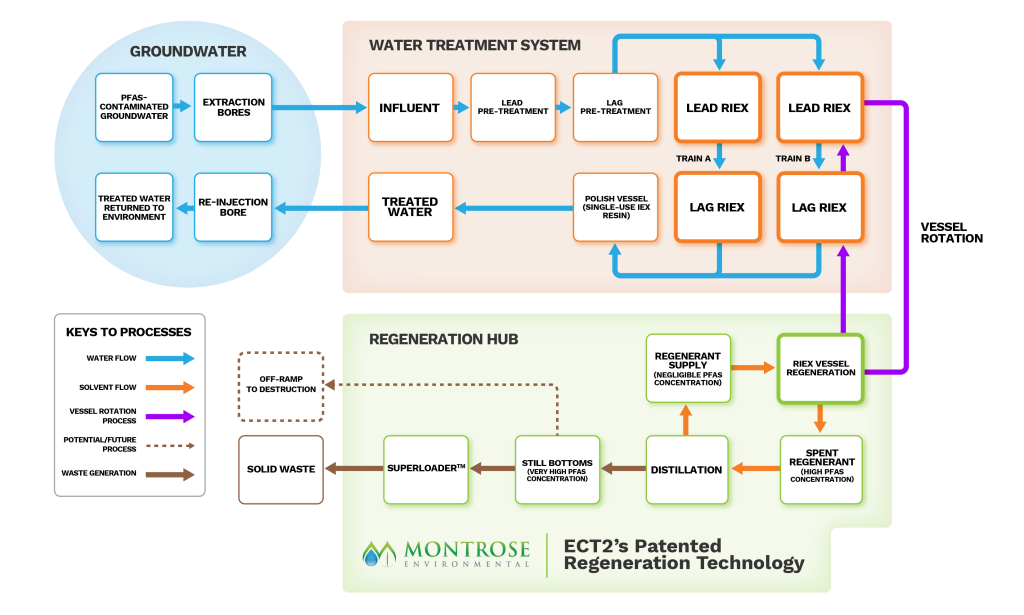

Following an evaluation of alternatives that considered expected change-out frequencies, waste generation rates, and overall lifecycle costs, RIEX emerged as the most viable and cost-effective treatment technology for full-scale implementation. The treatment system featured a multi-stage process (see below), with each stage contributing to the overall efficiency and thoroughness of PFAS removal.

The chosen regenerable resin, SORBIX RePure ion exchange resin, demonstrated high PFAS selectivity and equally high regeneration efficiency. The regeneration process uses a solvent/brine mixture, with an optimized number of bed volumes passed through a spent resin bed. Over 26 regeneration cycles have been performed since start-up, removing over 20-kg of PFAS without replacement of the RIEX media.

With an average total PFAS influent concentration of 16-µg/L (peaking at 60-µg/L), the system has continuously achieved 100 percent compliance with treatment objectives. In fact, the effluent from the lag resin vessel has never exceeded even one-third of the 70-ppt threshold for PFOS and PFHxS. Additionally, the media has sustained continual regeneration and reuse without loss of PFAS uptake capacity or physical breakdown.

The system is able to treat 500-million-l of water before the Superloader media requires change-out, which results in 600-l of waste for disposal. This equates to a concentration factor over 800,000 to 1.

Though RIEX is not applicable to all remediation operations, when PFAS concentrations are in the µg/L range and expected treatment duration times span years or decades, the economics often favor RIEX. Although there are higher upfront costs for a regenerable system, the long-term economics make it advantageous.

The operational success of this RIEX system highlights its effective and sustainable approach to combat PFAS while minimizing waste. By deepening our understanding of such systems, we progress together toward a cleaner, safer environment for all.

David Kempisty, Ph.D., P.E., is Director, Emerging Contaminants, ECT2/Montrose Environmental Group

More News from TME

-

Regenesis Offers Full-Spectrum PFAS Remediation

For project stakeholders and remediation managers confronted with PFAS, Regenesis demonstrates why in situ treatment using Regenesis’ PlumeStop® colloidal activated carbon (CAC) is a game changer. -

March 2024 Event – CDPHE Statewide PFAS Sampling Program Update

The Denver Metro Post of SAME hosts CDPHE to discuss and present updates on their statewide PFAS Sampling Program. -

Eliminating PFAS Leaching at Camp Grayling

At Camp Grayling, a novel colloidal-activated carbon material was used as a horizontal barrier on a site where aqueous film-forming foam had previously been discharged to prevent PFAS from leaching into groundwater.