An Installation of the Future: Planning, Programming, and Funding the Tyndall Rebuild

By Col. Robert Bartlow Jr., M.SAME, USAF

In the wake of Hurricane Michael, Tyndall AFB embarked on a visionary journey to become the “Installation of the Future”—a multi-layered program driven by reimagined master planning, resilient design, and flexible funding.

Editor’s Note: This is the second in a series of articles appearing in TME that detail and describe the recovery and rebuild of Tyndall AFB following Hurricane Michael, which struck the Florida Panhandle on Oct. 10, 2018. The multi-part feature covers the engineering challenges encountered by the U.S. Air Force, U.S. Army Corps of Engineers, and multiple private sector architecture-engineering firms and contractors to not only restore the base to operational status, but to transform it into the “Installation of the Future.”

Hurricane Michael made landfall on Oct. 10, 2018.

Tyndall AFB, located squarely in the Florida Panhandle where the Category 5 hit, endured 161-mph sustained winds. Severely damaged aircraft hangars, mangled metal structures, knocked down masonry walls, and snapped and bent pine trees would end up strewn across the installation. Michael became the costliest storm in history to strike a U.S. Air Force base. For several weeks, Tyndall’s future was uncertain.

In the months following the hurricane, and both during and after what proved to be an extensive and multi-faceted cleanup effort, discussions centered on the base’s future. The Air Force Directorate of Civil Engineering led the advocacy effort to secure the military construction funding for the recovery and resuscitation of Tyndall as the new home to three F-35 squadrons. While some on the Air Staff and also in Congress questioned if the base should be shut down, the future risks too high, visionary planners looked at this crossroads as an opportunity to not just rebuild, but transform it into the Installation of the Future.

Setting the Vision

At the six-week mark after the storm struck off the Gulf Coast, the Air Force Civil Engineer Center established the Tyndall Program Management Office (PMO). As the lead agency for the long-term recovery and rebuild of the base, initially under the leadership of Col. Scott Matthews, USAF, AFCEC Facility Engineering Director, the PMO began planning a near-total restoration of the base to full-mission capability. This generational opportunity, which could serve as a model for future base development across the military, was a planner’s dream.

Amy Vandeveer, AFCEC Installation and Planning Subject Matter Expert, arrived at Tyndall in mid-November 2018 and began to conduct asset management assessments with a small group of planners. Within days, Vandeveer and the planning team met with Col. Brian Laidlaw, USAF, Commander, 325th Fighter Wing, to present their “Plan to Plan” and gain his vision for the base. They also met with members of the 325th Civil Engineer Squadron, which provided the base master plan from the 2015 Tyndall Installation Development Plan. This document guided Team Tyndall in the allocation of resources to create a high-quality, safe, sustainable, and mission-ready installation.

Typically, a planning effort of this size takes close to three years, but planners only had six months.

As it were, the seeds for the Installation of the Future may have already been planted. Just a few months before Hurricane Michael, Laidlaw had presented his vision for the base in the “Tyndall Air Force Base Strategic Plan 2030.” Stated the opening line of the briefing: “Tyndall Air Force Base is entering a period of transition in its history. With transition comes opportunity.”

While none could have predicted the transition would come so soon and with so much destruction to trigger it, the facts remained: Tyndall was at the precipice of change. The 2015 master plan also had recommended that the base “demo facilities that have outlived their usable lifetime and focus our sustainment and facility modernization funds on consolidation of our work force into renovated, collaborative, tech-savvy work centers.”

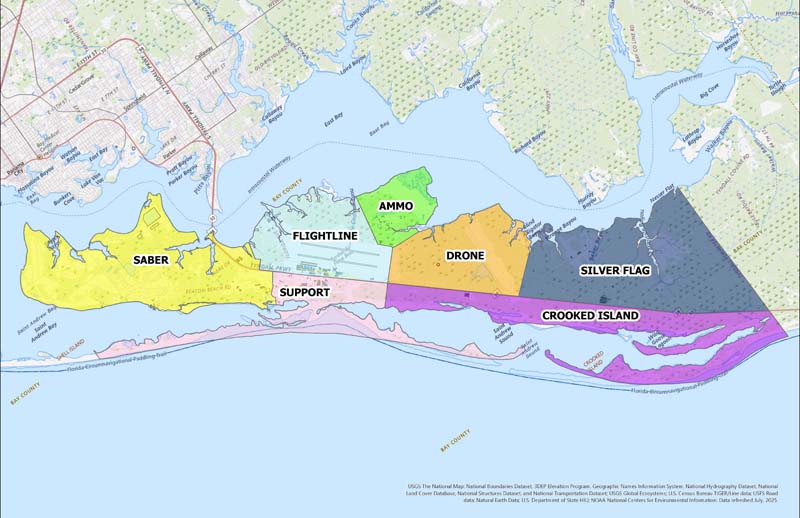

Typically, a planning effort of this size takes close to three years, but planners only had six months. In December 2018, a contract was awarded to AECOM to support the expedited effort. And the PMO applied the existing 2015 Installation Development Plan to achieve a resilient, right-sized installation. After much consideration and narrowing down district areas of the base, planners focused primarily on three sections: Flightline, Support, and Crooked Island. Leadership set the planning goals of resiliency, adaptability, and sustainability.

Programming Work

By January 2019, wing personnel and PMO staff were focused on the status of the damaged facilities, dividing them into three categories: red, yellow, and green. Red indicated that the facility was destroyed or damaged beyond repair and required military construction if it was to be replaced. Green denoted that a facility was repairable. Yellow indicated it could go either way.

The status of structures continuously changed in the early weeks and months. Assets labeled “damaged” required additional assessment because they were exposed to the elements until dried-in efforts were completed.

In his role leading the PMO, Col. Matthews started the programming process to rebuild the base. Programming was done using the Military Construction Project Data Sheet, the DD Form 1391. This systematic review and approval process ensured that resources aligned with Air Force missions and objectives. Completing this phase was a critical step in project development and programming. Both planning work and 1391 development are distinct and sequential steps in the overall military construction progression that must work together.

By mid-March 2019, Col. Brent Hyden, USAF, who had moved into the role of PMO Director, brought in the first group of programmers from Air Force Reserve Command and the Air National Guard. They began drafting DD 1391s needed for authorization and appropriation. These sheets summarized the need for a new facility and described the size and estimated cost.

The programming team aggregated projects into 12 zones for design and construction, and then compiled the front page 1391s and submitted them to their Air Staff counterparts. Although the first 1391s required to get the initial costs for 42 projects to Congress made it over the first hurdle, manpower was a concern. To meet the target date, the PMO needed advisory and assistance support services. In April 2019, the Air Force contracted with Jacobs Government Services under the Air Force Contract Augmentation Program to develop and complete DD 1391 packages for the 42 projects of the reconstruction program. Additionally, the scope of work included transitioning the master planning effort into zone development plans; conducting a thorough review of Tyndall’s existing facility standards prior to the storm to compare it to design standards in other hurricane and flood-prone areas and determine if internal standards needed updating; and developing the Installation Facility Standards Rebuild Appendix to the existing Tyndall Installation Facility Standards.

Ensuring Resilience. The planning team received additional guidance to alleviate Congressional concerns by ensuring that Tyndall’s infrastructure and facilities would apply resilient designs. Nancy Balkus, then-Deputy Director of Civil Engineers, sent two memoranda to AFCEC that drove design considerations.

- The first established Design Flood Elevation for new Tyndall facilities: 19-ft above today’s mean sea level on the Gulf side, and 14-ft above mean sea level on the East Bay side.

- The second memorandum adopted wind speed and building envelope protection criteria. The Tyndall PMO was directed to integrate the new 2019 Unified Facility Code 3-301-01 with Florida’s High Velocity Hurricane Zone best practices. These included a minimum design wind speed of 165-mph and required all exterior building envelope materials to have a Miami-Dade County Notice of Acceptance.

During facilitated charettes, planners gathered feedback from base leadership and Air Force stakeholders, covering a full range of options for existing and proposed facilities. Jacobs then developed the preferred alternative for future development, prioritized the sequencing of various projects, and prepared a cost estimate for each project.

By January 2019, wing personnel and PMO staff were focused on the status of the damaged facilities, dividing them into three categories: red, yellow, and green.

Defining Standards. At several workshops, hundreds of proposed architectural motifs and sketches were showcased. The Tyndall Fitness Center, built in 2010, was a cited example. Its curved roof became an architectural feature in the new proposed designs because the concrete masonry and roof had suffered minimal hurricane damage. Tyndall’s Installation Facility Standards defined architectural image and character, site and land management, and coastal resilience principles as the basis for the planning and design of buildings, sites, landscape improvements, roads and pathways, and landscape management zones.

Tyndall also continued to reimagine itself as a mission-ready, sustainable, and resilient base with integrated technology. By moving organizations previously located on the flightline, particularly the 325th Civil Engineer Squadron and Logistics Readiness Squadron, to locations set away from the flightline, valuable space was freed up. The site plan consolidated and collocated most of the administrative and community facilities as well; these previously had been spread across the base and suffered extensive damage. Overall, the master plan laid out a more walkable and bike-friendly community. Additionally, traffic engineering and safety analysis led to the realignment of roadways and intersections and the creation of a new commercial gate.

Sustaining Management

While work progressed at Tyndall, at the Pentagon, the Facilities Division within the Directorate of Civil Engineers continued to refine reconstruction costs. Using the Sustainment Management System (SMS), the team helped leadership decide when, where, and how to best maintain existing infrastructure by producing a common scoring set for priority planning. By downloading information from the SMS, the engineers took thousands of data points and built a massive spreadsheet to calculate the replacement cost for each piece of real property using the principles of the Air Force’s Cost Estimating Improvement Program.

Following this approach, the Facilities Division developed a Class 5 (rough order of magnitude) estimate per square foot/square meter. In addition, the team added a market factor to account for the expected massive increase in demand for labor and materials. Essentially, a military construction replacement cost was established for each piece of real property at Tyndall, then a cost factor added for post-hurricane conditions.

By January 2019, wing personnel and PMO staff were focused on the status of the damaged facilities, dividing them into three categories: red, yellow, and green.

Funding and Flexibility

Just over 14 months after Hurricane Michael devastated Tyndall, the National Defense Authorization Act for Fiscal Year 2020 was signed into law on Dec. 20, 2019. It declared approval from Congress “that the Secretary of the Air Force should restore Tyndall Air Force Base to achieve military installation resilience…and use innovative construction methods, materials, designs, and technologies in carrying out such restoration in order to achieve efficiencies, cost savings, resilience, and capability.”

Unlike the earlier appropriation, this legislation provided line-item authorization for individual projects at Tyndall, along with Offutt AFB in Nebraska and Virginia’s Joint Base Langley-Eustis (JBLE). Offutt was heavily damaged by flooding in March 2019 while JBLE, in the Hampton Roads area, was identified to received the F-22 mission from Tyndall as part of the overall strategic review and rebuild program (sidebar, page 48).

Overall, the master plan laid out a more walkable and bike-friendly community. Additionally, traffic engineering and safety analysis led to the realignment of roadways and intersections and the creation of a new commercial gate.

Tyndall’s historically significant construction program presented numerous challenges. Planners recognized that traditional construction funding was five-year money, which would not represent sufficient time. Success hinged on flexibility. Discussions with Congressional Defense Committee Staff led to requests for programmatic flexibility, which evolved into the FY2019 Supplemental and the December 2020 Veterans Administration/MILCON Bill “lump sum” appropriations.

Instead of individual line items for projects, funding from these appropriations could be moved between projects and across bases within the overall Natural Disaster Recovery Division. This eliminated the need to go back to Congress. Built on the extensive planning and programming at Tyndall as well as Offutt and JBLE, this critical flexible arrangement set up the program for success.

With the funding secured, the rebuild was ready to move ahead.

Securing Investment

Not everyone was in favor of reinvesting in Tyndall. During a May 2019 hearing for the House Armed Services Subcommittee on Readiness, discussions centered on vulnerability to future hurricanes and questioned the logic of rebuilding. Congress, however, made its ultimate intent known: authorizing and appropriating supplemental funding for Air Force disaster relief and recovery. By June 2019, Congress passed, and President Donald Trump signed, the $19.1 billion Additional Supplemental Appropriations for Disaster Relief Act of 2019.

This funding included $1 billion for planning, design, and construction expenses related to the consequences of Hurricane Michael, the military construction necessary to move Tyndall’s F-22s to Joint Base Langley-Eustis, Va., and also for the Air Force to recover from flooding that occurred in March 2019 at Offutt AFB, Neb. In addition to enabling this critical work, the bill included another $670 million in operations and maintenance funding for hurricane-recovery expenses.

Throughout the summer of 2019, the PMO teams at Tyndall and contractor support pushed to complete the full package of 1391s. By August 2019, the Air Force submitted 42 military construction projects to Congress—covering more than 200 pre-hurricane facilities. Included in the 2020 national defense bill, these projects totaled $2.8 billion in construction work and $147 million in design funding.

Col. Robert Bartlow Jr., M.SAME, USAF, is Chief of the Natural Disaster Recovery Division, Air Force Civil Engineer Center, Tyndall AFB, Fla.; robert.bartlow@us.af.mil.

Christine Walker, Public Affairs, AFCEC Natural Disaster Recovery Division, contributed to this article.

Published in the November-December 2025 issue of The Military Engineer

Check Out Related Articles From TME

-

A Standardized Approach to Aircraft Fire Training Infrastructure

To support enterprise-wide airmen readiness, the U.S. Air Force is modernizing its standard design for aircraft fire training facilities—introducing digital controls, dual-fuel systems, and PFAS-conscious infrastructure. -

Delivering Energetic Materials Manufacturing Facilities

Designing and constructing facilities that manufacture, process, handle, or store explosives and energetic materials present some of the most challenging defense projects—requiring technical experience, strict safety protocols, and a comprehensive understanding of regulatory frameworks. -

Forging Tradition and Innovation: A New Design Standard at Camp Lejeune

The II MEF Headquarters at Camp Lejeune blends Georgian Revival architecture with modern sustainability—delivering durability, efficiency, and precision that meets contemporary functional requirements while honoring heritage. -

Balancing Efficiency and Fiscal Responsibility

The continuing contracts clause offers the U.S. Army Corps of Engineers a way to improve project delivery and enhance fiscal responsibility by aligning funding with project execution. -

Next Steps for Digital Twin Development

U.S. Forces Japan is laying the groundwork for future integration of digital twin technology in order to validate and collect data that will offer comprehensive insights into utility conditions at installations and enhance overall decision-making, efficiency, and resilience. -

Generating Agile Technology

Through a collaborative program with the Naval Facilities Engineering and Expeditionary Warfare Center, a team of engineering students designed and prototyped a generator powered by ocean movement, with the aim to support the energy needs of warfighters in contested logistics environments.