By Abigail Rice

The generation and disposal of petroleum based plastic waste is a threat to water, air, and soil quality. Within expeditionary locations, plastic is a leading type of generated waste, with no adequate means for disposal. Conventional plastic water bottles account for up to 40 percent of supply tonnage moved on the battlefield.

Every year, single-use plastics make up more than 8-million-T of waste in the ocean while another 27-million-T enter landfills. Single-use plastic bottles can take upwards of 450 years to degrade in landfills, and even then, the consequences of the byproducts are highly toxic. Alternative, close-to-source methods are needed to reduce the negative impact to the environment and public health.

Bioplastics, such as polylactic acid, offer a compostable alternative to conventional plastics. An ongoing research project conducted by the U.S. Army Engineer Research & Development Center’s Construction Engineering Research Laboratory (ERDCCERL)investigated the degradation of bioplastics through the demonstration of a covered, forced-air compost system applicable to expeditionary operations. Results from the work lay the groundwork for further investigation of alternative disposal methods for plastic waste in military contingency environments.

DESIGN & DEMONSTRATION

The demonstration, conducted at CERL’s facilities in Champaign, Ill., used a commercial off-the-shelf, covered, forced-air compost system that allows for operation in a variety of climates. Additionally, it requires minimal technical skill and staff time to operate. The simplicity and controlled environment fit military engineering technology needs.

As part of the system, an engineered GORE cover is included to limit odors and emissions of volatile organic compounds, retain heat and , and allow for air movement. Oxygen moves through the compost pile by way of a blower system that allows for aerobic decomposition. The blower allows static and aerated composting with minimal turning required.

An interdisciplinary group of seven junior researchers and students without in-depth prior knowledge of composting operations received one day of training and completed set up of the system also in one day, with the support of two trained heavy machinery operators.

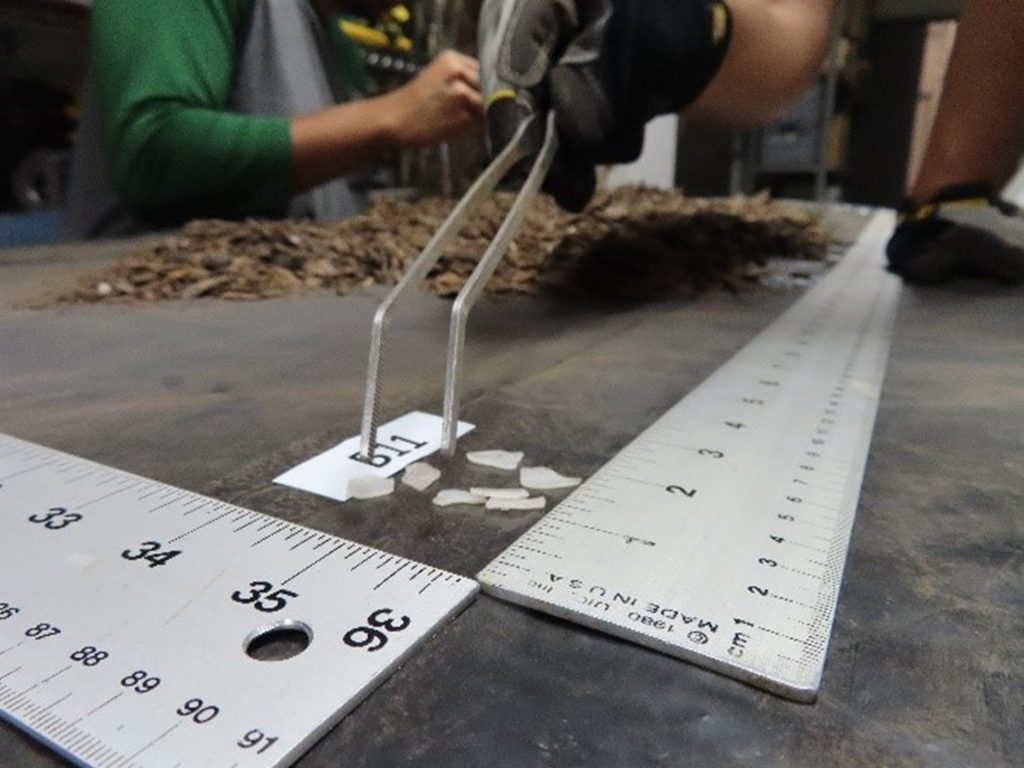

Measuring Degradation. The experimental design consisted of three untreated wood boxes with 12 slots each in a feedstock blend of brown waste (93 percent) and finished compost (7 percent). The compost pile measured approximately 2.44-m by 7.62-m by 7.62-m. In order to better understand the structural and dimensional effects on degradation, each box slot contained different sizes and quantities of bioplastic polylactic acid samples in 20-ounce cups. Size variations were 2.54-cm by 2.54-cm and 7.62 by 7.62-cm, with full and crushed cups. Differences in the sample size of polylactic acid were one, five, and 10.

The boxes were placed in different positions within the pile: Box B was placed in the center and above the blower system at 0.61-m; Box A was set furthest to the edge of the pile and 0.30-m high; and Box C was positioned mid-pile and 0.91-m high.

Observation Timeline. System operation was conducted over a six-week period, with remote monitoring and minimal oversight. Daily temperature, oxygen levels, and moisture content were monitored by a junior researcher for the experimental duration, with blower system conditions altered as needed. The compost pile reached 130°-F on day 10 (ensuring pathogen destruction) and then maintained 130°-F or higher throughout the remainder of the experiment.

A team of four junior researchers and students, along with two trained heavy machinery operators, completed take-down of the system in one day.

ANALYSIS & RESULTS

Samples were visually analyzed at three weeks and six weeks for degradation. To assess the degradation of the samples, photos and measurements were used to apply an ordinal scale from one through five (determined as the average score from two independent assessors).

Of the three boxes, Box A and Box C showed signs of decomposition at week three. At week six, they had degraded to about half a centimeter or less in size, with some having no visible sample remaining. Box B, located adjacent to the aerator, lagged in degradation and had, on average, the largest samples visually remaining at three and six weeks.

Random compost samples and near-box compost samples were sent to a third-party laboratory for analysis at both the three-week and six-week marks, as well as a baseline sample of the initial feedstock mix for comparison. All compost samples met standard metals and pathogen limits for compost quality. Additionally, all compost samples presented high carbon/nitrogen ratios, which indicated high amounts of nitrogen. This can be attributed to the use of untreated wood boxes that likely contributed a higher nitrogen content to the compost pile. All analyses determined that the finished compost was stable for applied use.

U.S. industrial compost standard ASTM 6400 states a 12-week period with no more than 10 percent of remaining product for the satisfactory disintegration of plastic materials. This military engineering technology demonstrated degradation of polylactic acid to ASTM 6400 standards for Box A and Box C after three weeks and for all three boxes after six weeks—cutting standard degradation time by at least half.

For future evaluation efforts, adjusting the sample collection methods to utilize stable polyethylene mesh bags in place of nitrogen-rich untreated wood boxes may allow for more interaction between the compost and sample, and further improve degradation rates as a result.

PROMISING ALTERNATIVE

The covered, forced-air compost system used in this demonstration proved promising as an alternative disposal method for bioplastics—requiring minimal training, oversight, and operation. Significant visual degradation was seen in as little as three weeks, with increased degradation after six weeks.

Increasing the use of bioplastics, when coupled with composting as a disposal method, would increase military waste diversion in support of goals laid out in recent executive orders and improve logistics management in contingency locations.

Further research on this covered, forced-air compost system in alternate environments, such as the desert or arctic, would provide insight into operability in these more extreme contexts. Continued investigation is critical to understand the limits of composting in all military operational domains for alternative disposal and subsequent environmental impact.

THE PLASTIC PROBLEM

According to the Environmental Protection Agency, waste entering landfills was the third highest contributor of human related methane emissions in the United States in 2019. Reduction of greenhouse gases is essential to alleviating climate change impacts and, in turn, economic and geopolitical threats to national security. Executive Orders 13990, 14008, and 14057 all outline commitments to greenhouse gas reduction in the United States.

Additionally, Executive Order 14057 targets a 50 percent reduction in waste disposal by 2025 and 75 percent by 2030. Per its implementing instructions, alternative disposal via waste-to energy will not count as diversion toward meeting the targets.

Other alternative source materials and disposal methods need to be explored. Utilization of bioplastics, such as polylactic acid, over petroleum-based plastic, and composting those materials over landfill, would directly support meeting the order’s targets for source reduction and diversion.

More News from TME

-

Eliminating PFAS Leaching at Camp Grayling

At Camp Grayling, a novel colloidal-activated carbon material was used as a horizontal barrier on a site where aqueous film-forming foam had previously been discharged to prevent PFAS from leaching into groundwater. -

Reaching Sustainability Goals with Waste-to-Energy

The U.S. Army Engineer Research & Development Center’s Construction Engineering Research Laboratory is working to develop small-scale waste-to-energy systems that will advance installation sustainability and waste management. -

Investigating Emerging PFAS Destruction Technologies

Following recent interim guidance from the Department of Defense on how military organizations are to handle the destruction and disposal of PFAS, developing technologies that target the destruction of these forever chemicals hold possibilities for effective and efficient removal.