In Situ Remediation in North Carolina

By Tracey Tapley, PG, M.SAME

An in-situ remediation strategy employed at a pair of Formerly Used Defense Sites in North Carolina helped achieve No Further Action status following years of stalled progress.

In 1986, an influential program was established that would be responsible for addressing legacy contamination at over 9,000 properties once operated by the Department of Defense: Formerly Used Defense Sites (FUDS).

Today, nearly 40 years later, cleanup has been completed at over 3,800 locations. Many of the sites supported fuel storage, distribution, and training during World War II and the Cold War; these past actions left behind petroleum hydrocarbons in soil and groundwater that can persist for decades.

The U.S. Army Corps of Engineers (USACE), the agency responsible for conducting remediation work through FUDS, is tasked with finding approaches that can quickly and effectively meet typically stringent cleanup goals to achieve regulatory closure and support beneficial reuse of the properties.

In North Carolina, two cleanup sites—Naval Auxiliary Air Station (NAAS) Edenton and NAAS Manteo—demonstrate the positive benefits of using a strategic in situ remediation approach.

Initial cleanup efforts in the mid-1990s included the removal of 10 aboveground storage tanks, three underground tanks, and associated pipelines, along with the excavation of more than 7,500-T of contaminated soil.

Longstanding Issues

Despite over-excavation of impacted soils and over a decade of monitored natural attenuation, residual contamination at Manteo and Edenton exceeded North Carolina’s Groundwater Quality Standards. To remediate the petroleum plumes at both sites, USACE implemented injections of colloidal activated carbon (CAC).

NAAS Manteo. In 2007, a release related to previous military operations at former NAAS Manteo was discovered. This prompted the removal of six underground storage tanks, 455-T of impacted soil, and 300-T of sludge. Then in 2011, an additional 1,366-T of contaminated soil was excavated. While these actions reduced contaminant mass, groundwater monitoring revealed persistent benzene, isopropylbenzene, and total petroleum hydrocarbons. After more than 10 years of monitored natural attenuation, contaminant concentrations plateaued.

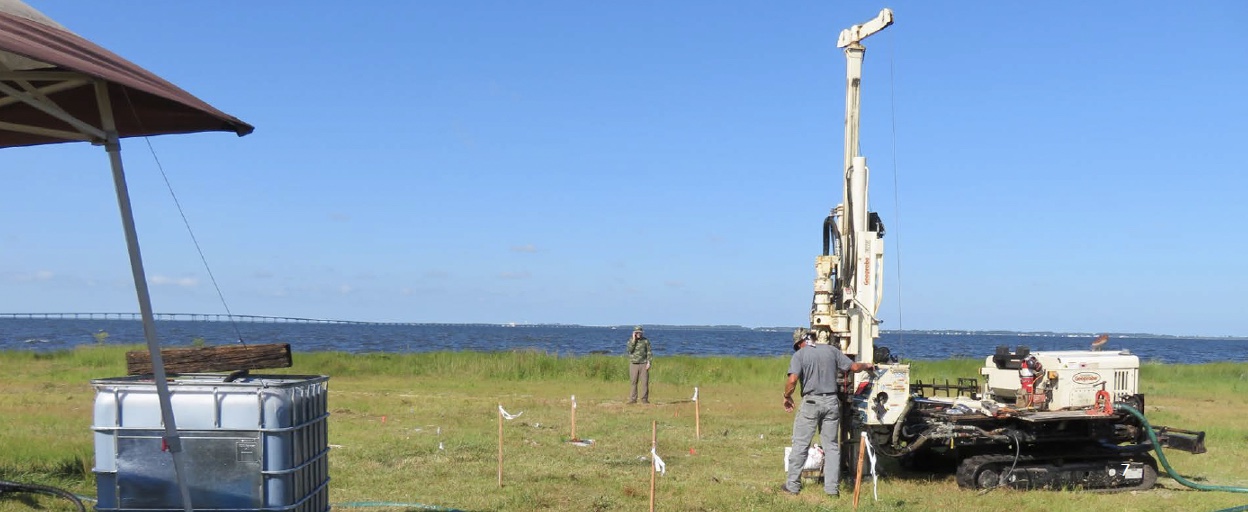

To accelerate site closure, in 2020, USACE and its industry partners injected approximately 23,300-gal of PetroFix (a water-based remediation fluid developed by Regenesis) into two residual plume areas encompassing more than 3,000-ft², using 68 hydraulic percussion-driven injection points. The injection interval spanned from 3-ft to 12-ft below ground surface, targeting the shallow aquifer zone most impacted by the release. Visual confirmation of PetroFix distribution directly into soil cores allowed the field team to adjust injection tooling and pressures to optimize coverage.

In 2021, the treatment area was expanded slightly after a monitoring well just outside the initial grid continued to show elevated concentrations. Following the supplemental application, groundwater sampling over four straight quarters demonstrated that all contaminants of concern were below regulatory limits, including benzene at 1-ppb. By 2023, the North Carolina Department of Environmental Quality issued a No Further Action. This determination brought closure to a petroleum release case that had remained open for over 15 years.

NAAS Edenton. When NAAS Edenton was decommissioned in 1958, responsibility for the property was transferred to local entities—but a legacy of petroleum contamination remained. Initial cleanup efforts in the mid-1990s included the removal of 10 aboveground storage tanks, three underground tanks, and associated pipelines, along with the excavation of more than 7,500-T of contaminated soil. While this work removed much of the source mass, groundwater monitoring revealed persistent impacts from benzene, naphthalene, and related hydrocarbons—exceeding groundwater quality standards.

In 2020, PetroFix injections were conducted across two target areas covering roughly 3,000-ft², using 33 direct-push injection points. During application, the field crew encountered “daylighting” at several locations near a monitoring well. This limited the distribution of the treatment solution in that area of the plume. Due to the daylighting, the injection plan was revised and a supplemental injection event was completed in 2021 that expanded the treatment area by 1,000-ft².

Following the injections, quarterly groundwater monitoring demonstrated all contaminants of concern had been reduced below stringent cleanup goals—benzene concentrations were sustained below 1-ppb for over 18 months.

In recognition of these results, the North Carolina Department of Environmental Quality issued a determination of No Further Action, successfully closing a site that had been in monitored natural attenuation for over 20 years.

Accelerating Cleanup

The successful remediation of NAAS Manteo and NAAS Edenton underscores the value of integrating innovative, resilient in situ technologies into the FUDS program. Across the country, many petroleum release sites share a similar trajectory: tanks and contaminated soils are removed, monitored natural attenuation is utilized, and yet residual plumes linger for years.

By applying a colloidal activated carbon formulation, USACE demonstrated a pathway to accelerate closure timelines while containing costs. The dual action of sorption and enhanced biodegradation provided immediate risk reduction and sustained treatment while meeting stringent groundwater standards. Importantly, both sites achieved No Further Action determinations following relatively modest injections.

The FUDS program will continue to face the challenge of addressing legacy petroleum contamination where conventional approaches have not delivered permanent effectiveness. More aggressive yet economical approaches are possible. The lessons learned in North Carolina offer a replicable system for projects nationwide—a model that emphasizes cost efficiency, long-term protectiveness, and returning properties to safe and productive use.

Innovative Treatment

The colloidal activated carbon formulation contains environmentally safe compounds that stimulate native microbes to break down hydrocarbons. This enhanced natural attenuation has been successfully used at similar petroleum hydrocarbon sites within the remediation industry. After treatment, groundwater plumes are often permanently eliminated.

Conventional monitored natural attenuation relies on periodic groundwater sampling to show that a contaminant plume is stable or shrinking. While these natural processes can reduce risk, they are often insufficient to meet stringent closure goals—such as the 1-ppb action level for benzene mandated by North Carolina. As a result, petroleum-contaminated sites may remain open for many years unless more proactive remedial measures are employed.

By distributing colloidal activated carbon throughout the affected zones, dissolved hydrocarbons are rapidly adsorbed onto the carbon surface, effectively removing them from groundwater. Meanwhile, the formulation’s additives (a blend of nitrate and sulfate compounds) stimulate native subsurface microbes to consume the contaminants as an energy source. This dual action of sorption and enhanced biodegradation shrinks closure timelines through fast-acting and lasting treatment.

By utilizing enhanced monitored natural attenuation strategies, closures can be accelerated, reducing the time that a site is in the monitoring phase compared to conventional strategies. Many of the methods are in situ, which minimizes disturbance, time to implementation, and costs.

Tracey Tapley, PG, M.SAME, is Senior Geologist, Geology/Hydrogeology and HTRW Design Section, USACE Savannah District; tracey.tapley@usace.army.mil.

Published in the January-February 2026 issue of The Military Engineer

Check Out Related Articles From TME

-

A Standardized Approach to Aircraft Fire Training Infrastructure

To support enterprise-wide airmen readiness, the U.S. Air Force is modernizing its standard design for aircraft fire training facilities—introducing digital controls, dual-fuel systems, and PFAS-conscious infrastructure. -

Delivering Energetic Materials Manufacturing Facilities

Designing and constructing facilities that manufacture, process, handle, or store explosives and energetic materials present some of the most challenging defense projects—requiring technical experience, strict safety protocols, and a comprehensive understanding of regulatory frameworks. -

Forging Tradition and Innovation: A New Design Standard at Camp Lejeune

The II MEF Headquarters at Camp Lejeune blends Georgian Revival architecture with modern sustainability—delivering durability, efficiency, and precision that meets contemporary functional requirements while honoring heritage. -

Balancing Efficiency and Fiscal Responsibility

The continuing contracts clause offers the U.S. Army Corps of Engineers a way to improve project delivery and enhance fiscal responsibility by aligning funding with project execution. -

Next Steps for Digital Twin Development

U.S. Forces Japan is laying the groundwork for future integration of digital twin technology in order to validate and collect data that will offer comprehensive insights into utility conditions at installations and enhance overall decision-making, efficiency, and resilience. -

Generating Agile Technology

Through a collaborative program with the Naval Facilities Engineering and Expeditionary Warfare Center, a team of engineering students designed and prototyped a generator powered by ocean movement, with the aim to support the energy needs of warfighters in contested logistics environments.