Mitigating PFAS at Naval Air Station Alameda

By Abram Eloskof, M.SAME, Robert Mayer, and Paul Hatzinger, Ph.D.

Historical firefighting training at the former Naval Air Station Alameda led to per- and polyfluoroalkyl substance impacts in the groundwater, necessitating the installation of a 720-ft permeable adsorptive barrier.

Historical activities at IR Site 14 at the former Naval Air Station Alameda in California included firefighting training, which introduced per- and polyfluoroalkyl substances (PFAS) into the first water bearing zone.

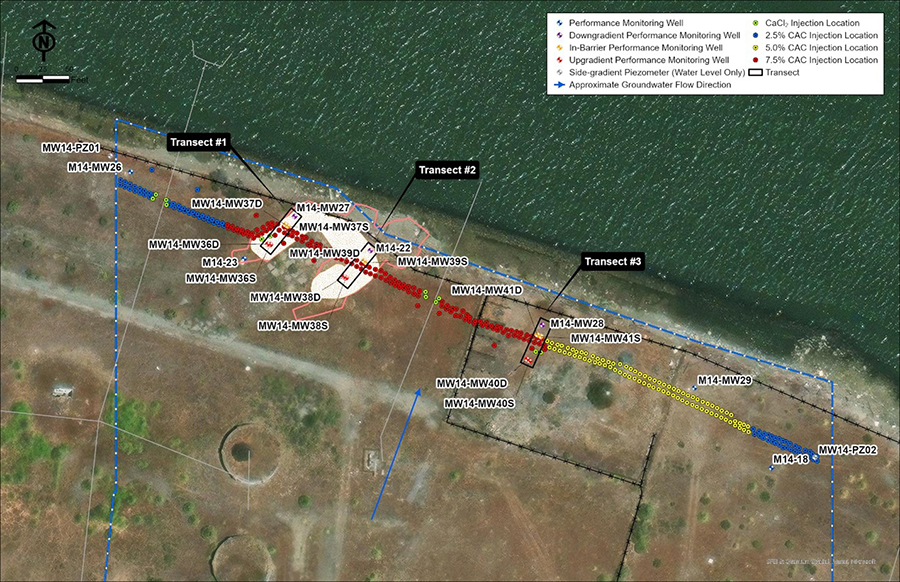

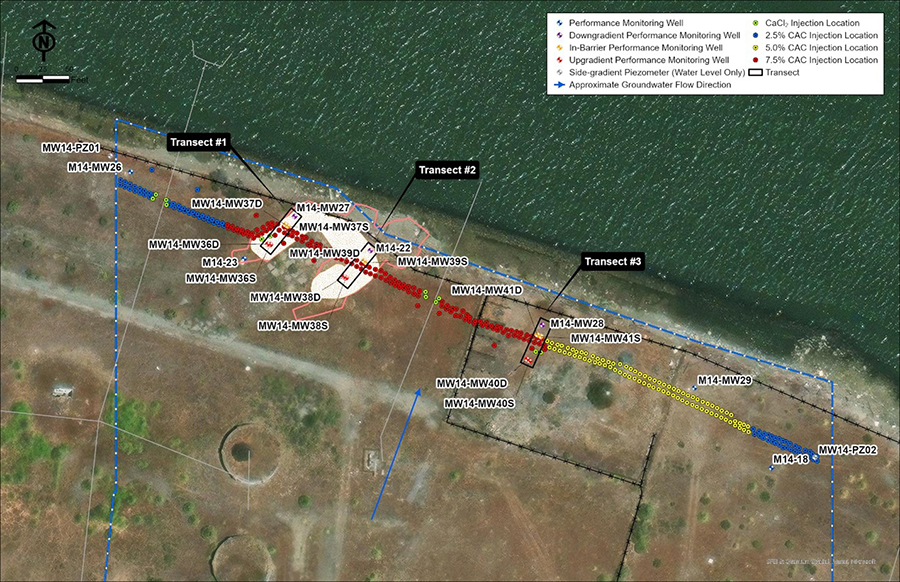

The shallow groundwater from IR Site 14 flows directly into the Oakland Inner Harbor. PFAS sampling revealed concentrations significantly above the Department of Defense’s screening levels, prompting the U.S. Navy to conduct a remedial investigation from 2022 to 2024. Based on the investigation, a design verification study and pilot test were initiated to evaluate an in situ permeable adsorptive barrier utilizing colloidal-activated carbon (CAC).

Informed Design

The design of the barrier was based on the results of laboratory column studies that were conducted using site soil and groundwater to assess the efficacy of CAC. Continuous soil coring provided detailed lithological confirmation. Discrete groundwater sampling analyzed PFAS and geochemical parameters that could affect the barrier design. A passive flux meter study assessed the advective PFAS mass flux into the barrier, and pre-application injection testing determined the CAC volume and injection point spacing required and assessed hydraulic limitations.

Using PFAS flux-based modeling, a 720-ft-long barrier was designed to intercept the shallow groundwater flow direction. The barrier was designed to operate for a 15-year service life, and accounted for contaminant mass flux through groundwater and PFAS back-diffusion from soil within the barrier’s footprint.

Leveraging Testing

The initial design for the barrier was based on the advective contaminant mass flux measurements in groundwater from passive flux meter data and validated by the remedial investigation results. A multi-compartmental model was later used to estimate PFAS contributions from soil desorption. By incorporating back-diffusion into the final design, the results of the bench-scale testing significantly increased the initial estimated CAC requirement from 145,000-lb up to 340,000-lb.

The final design incorporated variable CAC dosing along the barrier, ranging from 2.5 percent to 7.5 percent, with higher concentrations applied where PFAS mass loading was anticipated to be most significant.

Barrier Installation

Field injection equipment was mobilized to the site in summer 2023 to install the barrier. The installation work followed a double-row injection layout that consisted of 290 injection points spaced 5-ft apart. The target depth ranged from 1-ft to 15-ft below ground surface and encompassed the vertical shallow saturated zone. A hydraulic percussion drill rig was used, employing a bottom-up injection technique to ensure even distribution of the CAC.

A total of three monitoring well transects (located upgradient, within, and downgradient of the barrier) were used to monitor performance. Groundwater was collected via low-flow sampling, and PFAS was analyzed by Environmental Protection Agency Method 1633.

Monitoring of the site following the barrier installation included quarterly sampling of groundwater at 18 wells, with four events completed by the end of 2024.

- Transect 1. In-barrier wells saw perfluorooctane sulfonate (PFOS) and perfluorooctanoic acid (PFOA) reduced by over 99 percent—and downgradient wells saw PFOS and PFOA reduced by 99.7 percent.

- Transect 2. In-barrier wells saw PFOS and PFOA reduced by over 99.7 percent, and downgradient wells saw PFOS and PFOA reduced by 41 to 77 percent.

- Transect 3. In-barrier shallow wells saw PFOS and PFOA reduced by over 99.9 percent; in-barrier deep wells saw PFOS reduced by 63 percent and PFOA reduced by 72 percent; and downgradient wells saw PFOS and PFOA reduced by 52 percent and 82 percent, with a combined reduction of 78 percent.

Passive flux meters were deployed in a subset of Transect 1 and Transect 3 wells before the installation of the CAC barrier in June 2023, and again in August 2024, just over a year later, to evaluate the change in contaminant flux.

- Transect 1. At the in-barrier shallow well, PFOS mass flux was reduced from 16,316-µg/m²/day to 5.1-µg/m²/day between June 2023 and August 2024; deep zone PFOS flux decreased from 6,704-µg/m²/day to 0.0-µg/m²/day; and at the downgradient well, PFOS mass flux was reduced from 3,879-µg/m²/day to 96.9-µg/m²/day.

- Transect 3. At the in-barrier shallow well, PFOS mass flux was reduced from 16,687-µg/m²/day to 8.4-µg/m²/day between June 2023 and August 2024; and in the deep well, PFOS increased from 288-µg/m²/day to 608-µg/m²/day. The apparent increase in the deep well may be due to tidal influences and the increase in the Darcy velocity.

Protecting Ecosystems

The CAC-based barrier at former Naval Air Station Alameda represents a significant step forward in mitigating PFAS. Ongoing monitoring confirms that the barrier is effectively adsorbing PFAS, protecting sensitive aquatic ecosystems in the Oakland Inner Harbor.

This pilot effort showcases the potential of utilizing CAC to serve as a cost-effective and sustainable solution for managing PFAS contamination on defense installations and other government sites currently impacted by the forever chemicals.

Innovative Technology

The CAC utilized at IR Site 14 consists of a polymer-stabilized suspension of 1-µm to 2-µm particles. After injection via direct-push methods, the carbon distributes in the aquifer, attaching to solids and dramatically increasing adsorptive capacity for PFAS and other organic contaminants while minimally affecting hydraulic properties. In effect, CAC treatments create a below-ground activated carbon filter that sequesters PFAS.

This technology represents an energy-efficient approach to groundwater remediation, particularly when compared to an extraction and treatment approach. It is among just a few alternatives to prevent downgradient migration of PFAS in groundwater.

Its application to mitigate PFAS migration is currently under evaluation through the Navy’s Sustainability Development to Integration Program as well as the Defense Department’s Strategic Environmental Research and Development Program and the Environmental Security Technology Certification Program. Projects such as ER20-5182, ER21-1070, ER21-3959, and ER24-8200 are providing critical insights into PFAS remediation efficacy using this approach.

Abram Eloskof, M.SAME, is Vice President, Bayside Engineering Construction Inc.; abram.eloskof@baysideec.com.

Robert Mayeris Senior Scientist, Aptim, and Paul Hatzinger, Ph.D., is Director of Advanced Technology, Aptim Remediation and Technical Solutions. They can be reached at robert.mayer@aptim.com; and paul.hatzinger@aptim.com.

Published in the July-August 2025 issue of The Military Engineer

Check Out Related Articles From TME

-

A Standardized Approach to Aircraft Fire Training Infrastructure

To support enterprise-wide airmen readiness, the U.S. Air Force is modernizing its standard design for aircraft fire training facilities—introducing digital controls, dual-fuel systems, and PFAS-conscious infrastructure. -

Delivering Energetic Materials Manufacturing Facilities

Designing and constructing facilities that manufacture, process, handle, or store explosives and energetic materials present some of the most challenging defense projects—requiring technical experience, strict safety protocols, and a comprehensive understanding of regulatory frameworks. -

Forging Tradition and Innovation: A New Design Standard at Camp Lejeune

The II MEF Headquarters at Camp Lejeune blends Georgian Revival architecture with modern sustainability—delivering durability, efficiency, and precision that meets contemporary functional requirements while honoring heritage. -

Balancing Efficiency and Fiscal Responsibility

The continuing contracts clause offers the U.S. Army Corps of Engineers a way to improve project delivery and enhance fiscal responsibility by aligning funding with project execution. -

Next Steps for Digital Twin Development

U.S. Forces Japan is laying the groundwork for future integration of digital twin technology in order to validate and collect data that will offer comprehensive insights into utility conditions at installations and enhance overall decision-making, efficiency, and resilience. -

Generating Agile Technology

Through a collaborative program with the Naval Facilities Engineering and Expeditionary Warfare Center, a team of engineering students designed and prototyped a generator powered by ocean movement, with the aim to support the energy needs of warfighters in contested logistics environments.