Prefabricated Magazine Earns Protective Construction Designation

Sponsored Content, Presented by Armag

“It took years of development, collaboration, and hard work, but the result was a groundbreaking explosives storage magazine that delivers greater efficiency for our warfighters.”

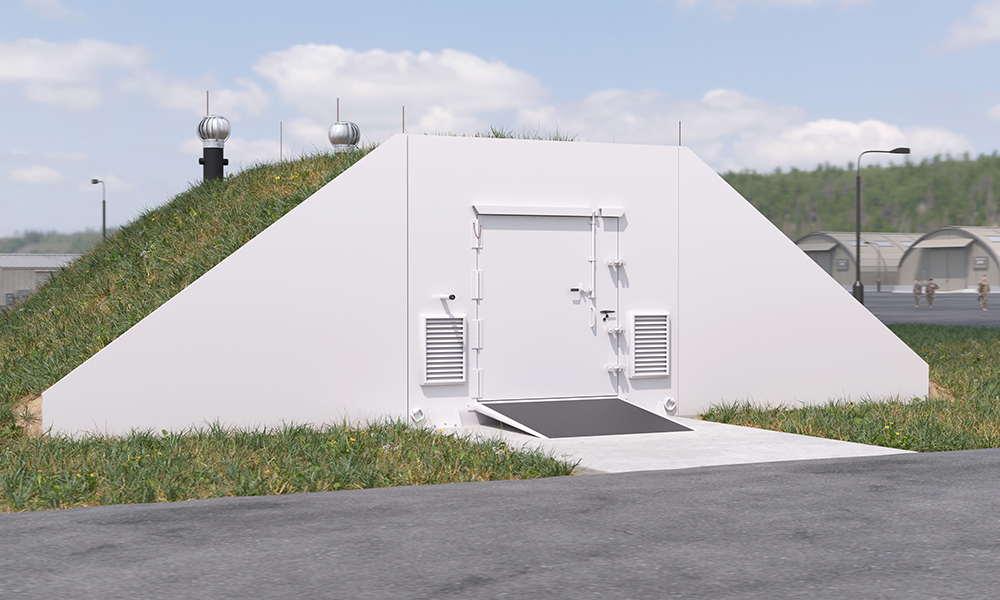

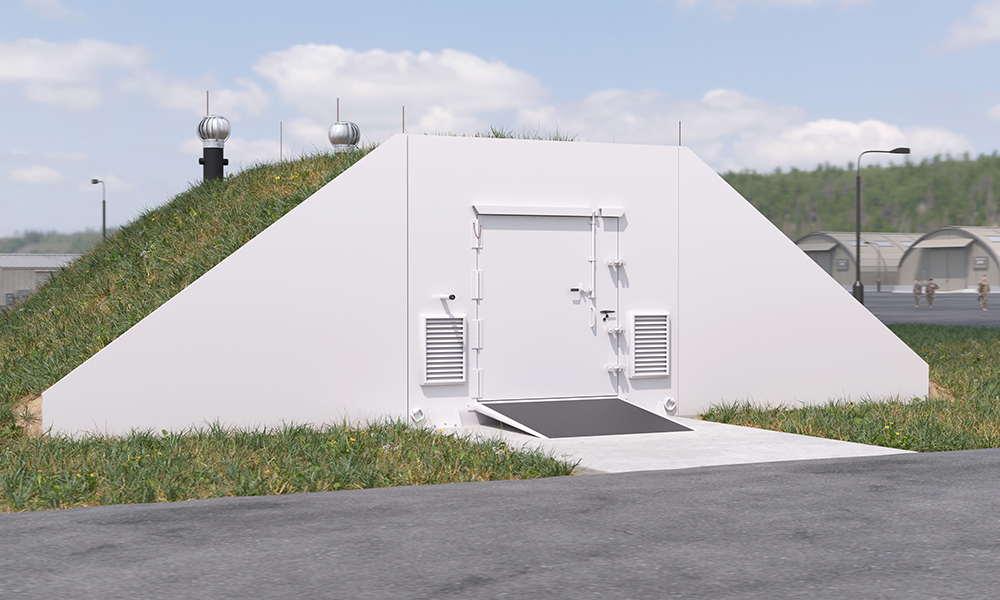

That is how Joseph Haydon, Vice President of Business Development at Armag Corporation, describes the company’s new 3-Bar Earth Covered Magazine (ECM). The innovative structure is the first of its kind, being the only prefabricated ECM with the ability to withstand external blast pressures equivalent to site-built ECMs. Accomplishing this feat required the development of new technology and input from many departments of the U.S. military.

The Armag 3-Bar ECM has been designated as “protective construction” by the Department of Defense Explosives Safety Board (DDESB) and will be officially referenced in DDESB Technical Paper 15 (References 1 and 2). The designation permits the Armag 3-Bar ECM to be located closer to other magazines and structures than typical prefabricated magazines. Its reduced Explosives Safety Quantity Distance hazard arc also facilitates a smaller footprint on the site plan.

As a mid-sized magazine, the Armag 3-Bar ECM can store up to 50,000-lb net explosive weight of ammunition or explosives. The 3-Bar design provides all these benefits without the cost of higher 7-Bar design and material requirements. Being prefabricated, it is manufactured off-site and delivered as a single piece, ready for installation—saving considerable time and cost.

Rigorous Forced Entry Testing

The Armag 3-Bar ECM completed rigorous forced entry testing to ensure complete physical security. A detailed test plan was designed by Stone Security Engineering, which also served as the forced entry consultant. Forced entry testing was conducted by Oregon Ballistics Laboratories.

This evaluation found that the prefabricated ECM provided greater than 10-min of forced entry resistance against a threat severity level III attack, as defined by UFC 4-026-01.

Gaining DDESB Adoption

Completing the stringent approval process on the Armag 3-Bar ECM was a monumental achievement. It required consensus from both the U.S. Army and the U.S. Navy before the DDESB would even consider the technology for adoption.

Development required close collaboration between Armag and multiple elements of the U.S. military. From the start, Armag worked with the Army Technical Center for Explosives Safety. Technical analysis and evaluation were conducted by subject matter experts in structural engineering and protective construction from the DDESB, the Army Corps of Engineers Engineering & Support Center, and the Naval Facilities Engineering and Expeditionary Warfare Center, located at Port Hueneme, Calif.

Soon to be adopted into TP-15, the Armag 3-Bar ECM is approved for use across the entire defense community.

Structure and Load Distribution

The Armag 3-Bar ECM is a steel box ECM with vertical walls and a flat roof. This allows for significantly better space utilization within the magazines compared to arch-roof ECMs. It is constructed of continuously welded steel sheets on all six sides. As a result, it is not susceptible to the cracking and leaking that often occurs in concrete ECMs. The roof load is engineered for both blast loads and standard loads (such as soil, dead load, or snow).

Protection from Harsh Climates

In addition to forced entry and blast resistance, Armag’s 3-Bar ECM provides protection against harsh climates. A system of lightning rods and grounding cables keeps the unit safe from lightning strikes. The steel headwall is protected with a zinc-rich primer and polyurethane topcoat, suitable for marine environments or environmental severity classification C5.

“The Armag 3-Bar ECM is a game changer. It allows customers to get the site planning benefits of an ECM with the cost savings of a prefabricated, off-the-shelf solution.”

— Tyler Ross

Director of Explosives Safety and Operations, The Schreifer Group

Ready for the Field

The Armag 3-Bar ECM is now available, manufactured by Armag Corporation entirely in its secured production facility in Bardstown, Ky. The result of years of development, it is a breakthrough in explosives storage technology, and it gives U.S. armed forces an efficient and capable option to support their mission.

Learn more at ArmagCorp.com/ecm.

More from TME

-

Measuring Success of an Onsite Wastewater System

The Louisville District of the U.S. Army Corps of Engineers played a critical role in designing an innovative septic mound system for the St. Charles Army Reserve Center, with recent evaluations indicating acceptable performance has been maintained years later. -

Identifying Contaminated Materials at Remediation Sites

Differentiating site-related wastes from naturally occurring or industrial background materials is critical for accurate remediation decisions and cost-effective cleanup. -

Complexities of PFAS Groundwater Interim Actions

With funding from the Environmental Security Technology Certification Program and oversight by the Defense Innovation Unit, a six-month groundwater treatment pilot study at Biddle ANGB revealed key insights into managing the challenges encountered in executing non-time critical removal actions concerning per- and polyfluoroalkyl substances.