By Mike McCullough, CIH, CSP, and Maj. Derick Chandler, PMP, M.SAME, USAF

Completing an audit of the hazards, permits, and roles and responsibilities associated with confined spaces can help alleviate health risks and enhance worker protections around these aspects of facilities.

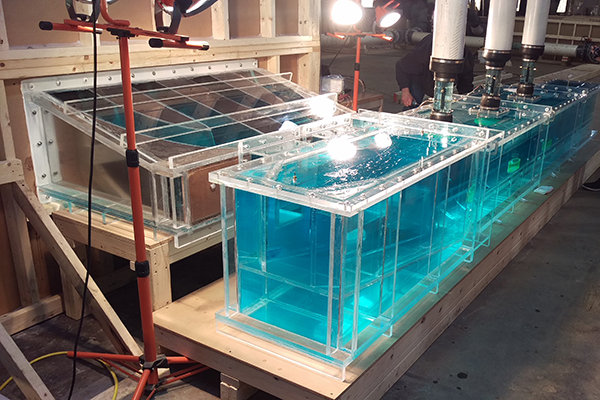

U.S. Air Force Photo by Mauricio Campino, 436th Airlift Wing Public Affairs

Confined spaces can pose a variety of health hazards for the workers who must enter them. Conducting an annual review of the Confined Space Entry Program is the best way for organizations to manage this risk. Through this effort, leadership can ensure that all changes are documented in its written procedures while also exploring ways to enhance effectiveness in safeguarding those individuals who work in or around confined spaces, including rescue personnel.

A complete audit of confined spaces includes inventory checks, hazard assessment, roles and responsibilities, labeling, permits, and rescue plans. The Occupational Health & Safety Administration maintains confined space standards for both maritime and construction settings with requirements for permit-required spaces.

Evaluating Spaces

The first step in a comprehensive confined space review is to inventory and evaluate the site in-person. Managers should ensure they have identified and catalogued all the confined spaces at their location. The most common way to define a confined space is that it is a large enough opening and shaped so that an employee can enter and perform work. Additionally, the entry or exit is restricted, or has limited openings. Finally, the space is not designed for continuous human occupancy during normal operating conditions. Some commonly overlooked examples of such confined spaces include HVAC systems, trash compactors, and dock locking systems.

After the completion of the inventory, it is essential to conduct an evaluation of each space to determine whether it falls under the category of permit required or non-permit required. This process is done by answering a series of determining questions.

- Is bodily entry possible?

- Is there limited/restricted access or egress?

- Is the space not designed for continuous human occupancy?

- Is there potential or actual hazardous atmosphere?

- Is there a potential for engulfment?

- Can the internal configuration trap or asphyxiate an entrant?

- Are there any other potential safety or health hazards present?

Confined spaces that only answer “yes” to the first three questions should be considered a non-permit-required confined space. Any “yes” to the last four questions would mean the space will fall into the category of permit required. However, in order to properly evaluate the answers to those questions, a hazard assessment of the space must be performed.

Assessing Hazards

A hazard assessment looks at multiple areas of concern that should be evaluated when attempting to determine if a confined space is permit-required. These areas included potential hazardous atmosphere, potential for engulfment, internal configuration, and other hazards.

Potential Hazardous Atmosphere. Identify any chemicals or physical agents that will be in the confined space prior to emptying, draining, or cleaning—or are reasonably expected to be introduced during any subsequent activities in or around the space. Examples include nitrogen, carbon dioxide, heat, dust, oil, water, ammonia, caustics, acids, flammables, combustibles, and welding fumes. Once hazards are identified, specify the controls that are used to eliminate the atmospheric hazard or reduce the hazard to an acceptable level. These involve emptying, draining, blanking, cleaning, washing, purging, ventilating, and use of personal protective equipment.

Potential for Engulfment. Detail the contents of all lines going into the confined space, including raw material and product lines. Specify the control isolation devices, such as locking out the incoming lines, inserting a flange in the line, and the use of double block and bleed procedures, as well as their locations.

Internal Configuration. Highlight any characteristics in the shape of the confined space that may pose a hazard. Identify the controls used to mitigate internal configuration of the space, like platforms, scaffolds, or work practices.

Other Hazards. Identify any other hazards that may be present in the space. Examples include sharp edges and pressurized lines, or mechanical, electrical, and thermal hazards. Controls will vary based on the specific risk but could include actions such as locking out potential moving parts, covering potential contact hazards, and the use of additional personal protective equipment.

Properly labeling confined spaces can improve a program greatly. Hatches, doors, and other access points must be labeled to prevent unauthorized entry. The type of label or sign required is typically determined by the result of a confined space hazard analysis and whether it is a permit-required or non-permit-required space. For permit-required spaces, the suggested labeling is: “Danger: Permit Required Confined Space. Do Not Enter. Authorized Personnel Only.” For non-permit-required confined spaces, the suggested labeling is: “Caution: Non-Permit Required Confined Space. Do Not Enter. Authorized Personnel Only.”

While it is at times acceptable to use similar language to meet the requirement for a label or sign, it is recommended to use consistent language across a location.

Scenario Planning

Every confined space program should have both emergency and rescue procedures listed out for the worst-case scenario. Each site in a Confined Space Entry Program should have a rescue plan that considers factors specific to the confined space. These include the hazards most likely to be encountered during a rescue; size and configuration of the space; and response time required based on the foreseeable hazards and risks encountered during the entry and associated rescue).

There are several steps, at a minimum, that a site rescue plan should include.

- Identification and designation of trained rescue personnel who are available where permit-required confined space entries are conducted, including whether the service will be internal or external.

- Awareness and placement of rescue personnel and equipment based on the hazards to ensure adequate response time.

- Equipment needed for confined space rescue.

- The type of rescue required (non-entry rescue versus entry rescue).

- Means to summon rescuers in a timely, safe manner.

- Atmospheric monitoring expectations for rescue personnel.

- Personal protective equipment required to protect rescue personnel.

- Provisions for situations when rescue personnel are unavailable or become unavailable.

Affected employees should practice rescues at least once every 12 months. An actual rescue can substitute as a drill for members who participated in the rescue as long as the team members participate in a post-event discussion or training on the incident. If external rescue services are utilized at the facility, the site must ensure they are familiar with the configuration and hazards associated with the confined spaces. This familiarity can be provided through a site tour or conducting a confined space rescue exercise. A documented review of the site rescue equipment should be conducted prior to any permit-required confined space entry to ensure that all required rescue equipment is in usable condition and readily available.

Protecting Workers

Confined spaces can pose a variety of hazards, especially at military installations where sites may be restricted or difficult to access, but these threats can be mitigated through proper planning and caution.

Leaders responsible for confined space entry programs should leverage their next audit to find opportunities to improve their program and make it more effective at protecting the workers impacted. A well-defined confined space program not only helps with annual audits, but saves lives.

Defining Key Roles

The “Roles and Responsibilities” of the Confined Space Entry Program provides an opportunity to set and reinforce clear expectations as leaders. You may want to specify your role in acknowledging ownership and support to ensure the full funding and endorsement of all program elements. Clearly communicate your support for individuals who refuse to enter a permit-required space if all elements of the permit are not complete. Ensure adequate time and funding are allocated for completing the required training and acquiring necessary equipment.

Another role you may want to expand is the Program Coordinator. Clearly define that this person should have the knowledge required to understand the process of classifying confined spaces, including recognition and identification of hazards (inherent, adjacent, and introduced), which can lead to reclassifying non-permit required confined spaces as permit required. Expanding on the required training and experience for this role may help in ensuring that adequate training is fully supported and funded. In addition, it also may assist in identifying the correct person to serve in this crucial role.

Mike McCullough, CIH, CSP, is Senior Project Manager, QTS Group; mmccullough@qtsgrp.com.

Maj. Derick Chandler, PMP, M.SAME, USAF, is Bioenvironmental Engineering Flight Commander, Joint Base Andrews, Md.; dnchan19@gmail.com.

More News from TME

-

Developing an Engineering Standard of Care for Cyber Safety

There is growing urgency to secure the nation’s critical infrastructure from a cyberattack, which will require improvements in both federal policies and day-to-day operations to strengthen response and recovery from incidents. -

Improving Escalation Forecasting in Federal Construction

A newly developed escalation forecasting methodology for major capital acquisition projects improves on previous models with a Monte Carlo simulation to increase accuracy. -

Setting Standards For the Future at Norfolk Naval Shipyard

The renovation for Dry Dock 4 at Norfolk Naval Shipyard, utilized advanced 3D and scale modeling to guide the design choices that would prepare the facility for another 50 years of service while meeting increased standards for resiliency and redundancy.